Building a personal computer represents one of the most rewarding experiences in modern technology, yet it simultaneously presents numerous opportunities for catastrophic component failure. The delicate nature of contemporary computer hardware, combined with the complex interdependencies between various subsystems, creates an environment where a single misstep can result in hundreds or thousands of dollars in damaged components. Understanding these potential pitfalls and implementing proper preventive measures becomes essential for anyone attempting to assemble their own computer system.

The modern PC building landscape has evolved significantly over the past decade, with components becoming increasingly sophisticated yet paradoxically more fragile. Current generation motherboards feature thousands of microscopic surface-mounted components, processors utilize nanometer-scale manufacturing processes, and memory modules operate at frequencies that would have been considered impossible just a few years ago. This technological advancement has created new vulnerabilities that builders must understand and respect throughout the assembly process.

Workspace Preparation and Environmental Considerations

The foundation of successful PC building begins long before touching any components, starting with proper workspace preparation. Many builders underestimate the critical importance of environmental factors, leading to preventable damage through inadequate preparation. The ideal building environment maintains consistent temperature and humidity levels, as extreme variations can cause components to expand or contract, potentially leading to microscopic stress fractures or connection failures.

Temperature control becomes particularly crucial when working with thermal interface materials and mechanical components. Thermal paste consistency changes dramatically with temperature variations, affecting application techniques and curing properties. Additionally, metal components experience thermal expansion and contraction that can affect fitting tolerances and mounting pressures. Maintaining a stable room temperature between 65-75 degrees Fahrenheit provides optimal conditions for component handling and installation.

Humidity control represents another often-overlooked aspect of workspace preparation. Excessively dry conditions increase static electricity accumulation, while high humidity can cause condensation formation on cold components brought in from different environments. The optimal relative humidity range falls between 40-60 percent, providing sufficient moisture to dissipate static charges without risking condensation damage.

Lighting quality directly impacts assembly accuracy and component protection. Inadequate lighting forces builders to work closer to components, increasing the risk of accidental contact or dropped tools. Professional-grade LED work lights provide consistent, shadow-free illumination that reveals fine details without generating excessive heat. Positioning multiple light sources eliminates shadows and provides clear visibility of all working areas, reducing the likelihood of installation errors.

Static Electricity: The Silent Component Killer

Electrostatic discharge represents perhaps the most insidious threat to modern computer components, capable of causing immediate catastrophic failure or subtle damage that manifests weeks or months later. Contemporary integrated circuits operate at increasingly lower voltages, making them exponentially more susceptible to static damage. While humans cannot feel static discharges below approximately 3,000 volts, computer components can be permanently damaged by discharges as low as 30 volts.

The mechanisms of static electricity generation during PC building are numerous and often unexpected. Synthetic clothing materials, common in modern apparel, act as excellent static generators when combined with low humidity environments. Foam packaging materials, while providing excellent physical protection, can generate substantial static charges when removed or manipulated. Even seemingly innocent actions like walking across carpeted surfaces or handling plastic components can accumulate dangerous charge levels.

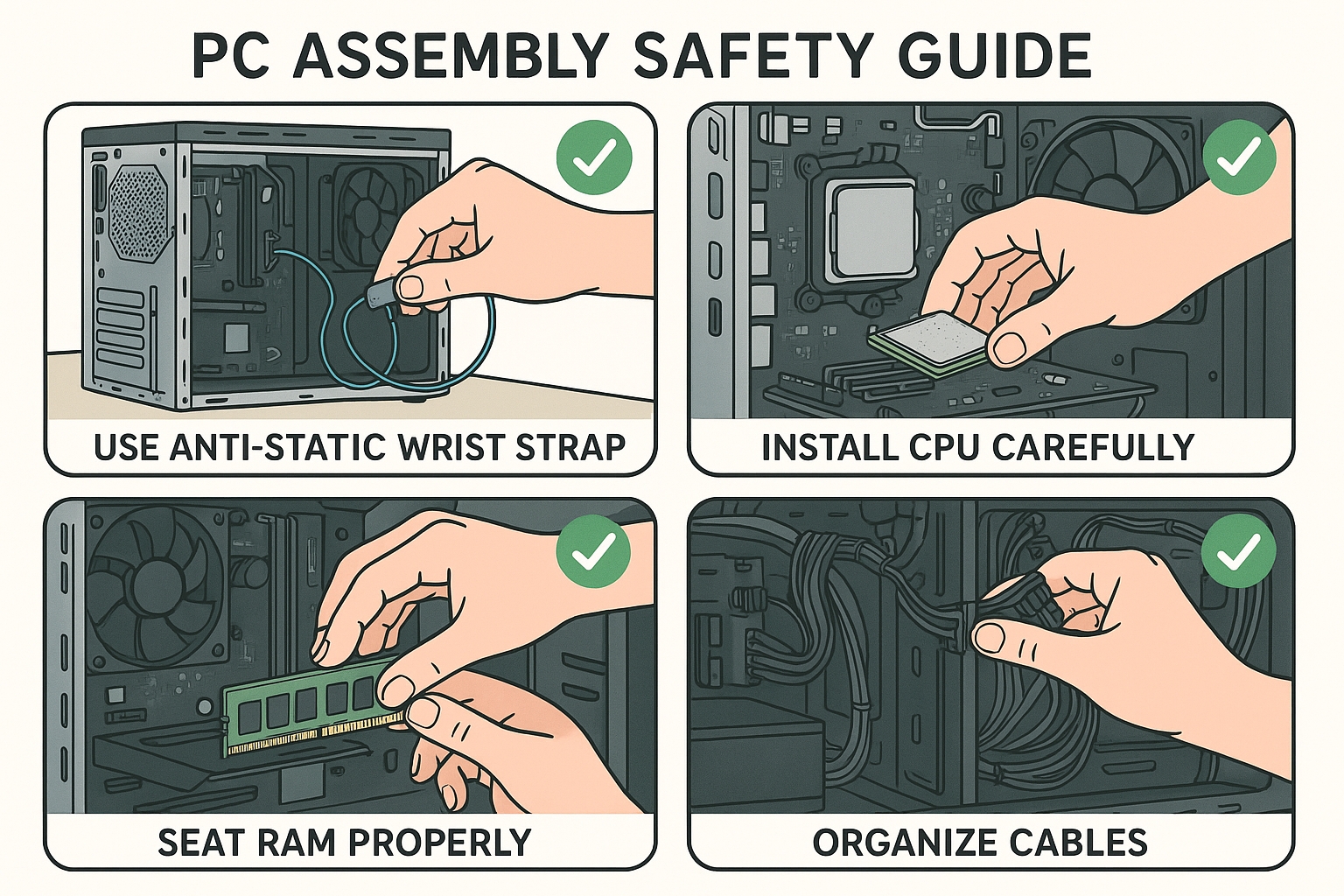

Proper static protection requires a multi-layered approach extending beyond simple anti-static wrist straps. Professional builders utilize anti-static work surfaces, conductive floor mats, and ionizing air blowers to create comprehensive static-free environments. The grounding system must provide a reliable path to earth ground, typically through the building’s electrical system or dedicated grounding points. Regular testing of grounding equipment ensures continued protection throughout the building process.

Component handling techniques play a crucial role in static protection. Always handle circuit boards by their edges, avoiding contact with exposed traces, connectors, or integrated circuits. Remove components from anti-static packaging only when ready for immediate installation, minimizing exposure time to potential static sources. When temporary placement becomes necessary, use anti-static foam or bags rather than standard surfaces that may accumulate charge.

Processor Installation: Precision and Patience

Modern processor installation represents one of the most critical and potentially destructive phases of PC assembly. The evolution from pin-grid-array (PGA) designs to land-grid-array (LGA) configurations has shifted the mechanical vulnerability from the processor to the motherboard socket, creating new failure modes that require different handling approaches. Current generation sockets contain thousands of delicate spring-loaded pins that can be easily damaged through improper handling or installation techniques.

Socket protection begins with understanding the mechanical design and operational tolerances of modern CPU sockets. Intel’s LGA sockets utilize a complex load plate and retention mechanism that applies precise pressure across thousands of individual contact points. Any foreign material, excessive force, or misalignment can permanently damage these microscopic connections. The socket cover provided with new motherboards must remain in place until the moment of processor installation, protecting the delicate pins from contamination or accidental contact.

Processor alignment represents a critical skill that requires careful attention to orientation markers and mechanical guides. Modern processors incorporate multiple alignment features including corner notches, pin patterns, and orientation markers that must align perfectly with corresponding socket features. Attempting to force a misaligned processor can result in bent socket pins, damaged processor contacts, or fractured substrate materials. The processor should drop into place with minimal pressure when properly aligned.

The load plate mechanism demands understanding of proper operating procedures and force requirements. Closing the retention arm requires significant force that can feel uncomfortable to inexperienced builders, leading to incomplete installation or attempts to reduce clamping pressure. However, insufficient clamping force results in poor electrical contact and potential thermal issues. The retention arm must close completely and latch securely, even though the required force may seem excessive.

Socket Protection and Installation Guidelines

| Component | Protection Method | Installation Technique | Common Mistakes |

| LGA Socket Pins | Keep socket cover until installation | No direct contact, visual inspection only | Touching pins, dropping debris |

| CPU Substrate | Handle by edges only | Align orientation markers precisely | Forcing misaligned processor |

| Load Plate Mechanism | Avoid excessive manipulation | Apply firm, consistent pressure | Incomplete retention arm closure |

| Contact Surfaces | Keep clean and debris-free | Single installation attempt preferred | Multiple installation attempts |

Thermal Interface Material Application

Thermal paste application represents a deceptively complex process that significantly impacts both immediate system functionality and long-term component reliability. The primary function of thermal interface material involves filling microscopic imperfections between the processor heat spreader and cooling solution, creating an efficient thermal transfer path. However, improper application techniques can result in inadequate cooling, component contamination, or even electrical damage in extreme cases.

Understanding thermal paste properties becomes essential for proper application. High-quality thermal compounds exhibit specific viscosity characteristics that determine spreading behavior and coverage patterns. Temperature affects paste consistency, with cold paste requiring more force to spread while warm paste may flow excessively. Room temperature application provides optimal handling characteristics and predictable coverage patterns.

Application quantity represents the most common source of thermal paste errors. Excessive paste application creates several problems including spillover onto surrounding components, poor heat transfer due to thick thermal barriers, and potential electrical conductivity issues with metal-based compounds. Conversely, insufficient paste application results in air gaps and inadequate thermal transfer. The optimal amount typically resembles a grain of rice for standard processors, though this varies with processor size and heat spreader design.

Spreading techniques have evolved with modern processor designs and paste formulations. Traditional manual spreading has been largely superseded by compression spreading, where the cooling solution mounting pressure distributes the paste automatically. This approach reduces contamination risk and provides more consistent coverage. However, manual spreading may still be necessary for certain cooling solutions or specialized thermal compounds.

Motherboard Installation and Mechanical Considerations

Motherboard installation presents numerous opportunities for mechanical damage due to the large size, complex shape, and inherent flexibility of modern printed circuit boards. Contemporary motherboards utilize multi-layer designs with embedded power planes and signal layers that can be damaged through excessive flexing or inappropriate mechanical stress. Understanding proper support and mounting techniques becomes crucial for preventing both immediate damage and long-term reliability issues.

Standoff installation and verification represents the foundation of proper motherboard mounting. Missing standoffs create unsupported areas that flex under component weight or installation forces, potentially causing trace damage or component detachment. Conversely, extra standoffs not corresponding to motherboard mounting holes can create pressure points that bow the board and stress components. Each motherboard form factor specifies exact standoff locations that must be followed precisely.

The mounting sequence affects stress distribution and installation difficulty. Installing screws in a random pattern can create uneven tension that bows the motherboard, while the proper cross-pattern sequence distributes forces evenly. Beginning with corner screws and working toward the center ensures proper board alignment and reduces stress concentrations. Torque control becomes important, as over-tightening can crack the board while under-tightening allows movement and connector stress.

Input/output shield installation often receives inadequate attention despite its impact on motherboard stress and connector alignment. Improperly installed I/O shields can create pressure points that force motherboard connectors out of alignment, making peripheral connections difficult and potentially damaging connector housings. The shield must seat completely and provide support for all connectors without creating binding or excessive pressure points.

Memory Module Installation and Socket Protection

Modern memory installation has become increasingly complex with the introduction of higher density modules, increased operating frequencies, and tighter mechanical tolerances. DDR5 memory operates at significantly higher frequencies than previous generations, making proper installation techniques crucial for both system stability and component longevity. The increased pin count and reduced pin pitch of current memory modules creates new failure modes that require careful attention to installation procedures.

Socket preparation and inspection prevent many memory-related installation problems. Memory slots accumulate dust and debris that can interfere with proper seating and electrical contact. Visual inspection should verify that retention clips operate smoothly and that no foreign material occupies the slot. The notch alignment must be verified to ensure module compatibility and prevent forced installation of incompatible memory types.

Installation force requirements have increased with modern memory designs, often requiring more pressure than builders expect. However, excessive or uneven force can damage both the module and socket. Proper technique involves applying firm, even pressure directly downward until the retention clips engage automatically. Angled insertion or rocking motions can damage pins or crack the module substrate.

Memory module timing and sequence become important in multi-module installations. Installing modules in the incorrect slots can prevent proper dual or quad-channel operation, reducing system performance significantly. Additionally, installing modules with different specifications can cause stability issues or prevent system operation entirely. Following motherboard documentation for memory slot population ensures optimal performance and compatibility.

Memory Installation Best Practices

| Installation Phase | Critical Checkpoints | Force Requirements | Failure Indicators |

| Pre-Installation | Socket cleanliness, clip operation | Minimal for inspection | Debris, damaged clips |

| Module Alignment | Notch positioning, even seating | Light guidance pressure | Binding, uneven gaps |

| Final Seating | Automatic clip engagement | Firm, consistent downward | Incomplete seating, clip failure |

| Verification | Module fully seated, clips secure | None – visual only | Visible gaps, loose clips |

Graphics Card Installation and PCIe Considerations

Modern graphics card installation presents unique challenges due to the substantial size, weight, and power requirements of contemporary GPUs. High-end graphics cards can weigh several pounds and extend well beyond standard expansion slot boundaries, creating mechanical stress points that can damage both the card and motherboard if not properly managed. The combination of thermal expansion, gravitational forces, and connector stress requires careful attention to support and alignment throughout the installation process.

PCIe slot preparation involves understanding the mechanical and electrical characteristics of modern expansion slots. PCIe 4.0 and 5.0 slots operate at significantly higher frequencies than previous generations, making proper electrical contact crucial for system stability. Any contamination or damage to slot contacts can result in intermittent failures or reduced performance. Visual inspection should verify clean contacts and proper retention clip operation before attempting card installation.

The installation sequence becomes critical with large graphics cards that may interfere with other components or cables. Installing the graphics card before routing cables can make cable management difficult or impossible, while installing it after cable routing may require cable repositioning. Planning the installation sequence prevents rework and reduces the risk of component damage from repeated handling.

Mechanical support considerations have become increasingly important as graphics cards have grown larger and heavier. Many modern cards require additional support beyond the PCIe slot retention mechanism to prevent long-term damage from gravitational stress. Anti-sag brackets, support posts, or vertical mounting solutions distribute the card weight and reduce stress on the motherboard slot and card substrate.

Power Supply Connection and Cable Management

Power supply connections represent one of the most overlooked sources of component damage during PC assembly. Modern systems utilize multiple high-current connections with increasingly compact connector designs that require specific insertion techniques and force levels. Improper connector installation can result in inadequate electrical contact, overheating, or even component damage from incorrect voltage delivery.

The 24-pin main power connector exemplifies the challenges of modern power connections. This connector carries multiple voltage rails with specific pin assignments that must align perfectly for proper system operation. The connector requires substantial force to seat completely, but excessive or angled force can damage both the connector and motherboard socket. The installation technique involves firm, straight pressure while ensuring even engagement across the entire connector width.

CPU power connections have evolved to include multiple 8-pin connectors for high-performance processors, creating new installation challenges. These connectors often mount in confined spaces with limited access, making proper installation difficult. Additionally, the high current capacity of these connections makes proper contact essential for system stability and safety. Incomplete insertion can result in arcing, overheating, or component damage.

PCIe power connections for graphics cards present their own unique challenges due to space constraints and cable routing requirements. Modern graphics cards may require multiple 8-pin connections or newer 12VHPWR connectors that handle significantly higher power levels. Proper cable routing prevents stress on connectors and ensures adequate clearance for cooling systems.

Cable Management and Airflow Optimization

Effective cable management extends beyond aesthetics to encompass system safety, thermal performance, and long-term reliability. Poorly managed cables can interfere with cooling airflow, create mechanical stress on connectors, or even contact moving parts like fans. Modern systems with high-performance components generate substantial heat that requires optimized airflow patterns, making cable management a critical aspect of system design.

Routing strategies should consider both immediate installation requirements and future maintenance needs. Cables routed through areas that require component access complicate future upgrades or troubleshooting. Additionally, cables subject to repeated flexing during system maintenance can develop fatigue failures that compromise electrical connections. Strategic routing minimizes both current installation difficulty and future maintenance complications.

Connector stress relief becomes increasingly important as cable lengths and routing complexity increase. Sharp bends near connectors concentrate mechanical stress that can damage internal conductors or connector housings. Maintaining gentle curves and avoiding stress concentration points extends cable life and maintains reliable connections. Cable ties and routing guides help maintain proper positioning while preventing excessive stress.

Thermal considerations in cable management include both direct thermal effects and airflow impact. Cables positioned near heat sources can experience accelerated aging that affects electrical properties and mechanical integrity. Additionally, cables that obstruct cooling airflow can create hot spots that impact component reliability. Strategic routing maintains both electrical integrity and thermal performance.

Critical Installation Checkpoints and Verification Procedures

| System Component | Primary Risk Factors | Verification Method | Recovery Options |

| CPU Installation | Socket pin damage, thermal paste contamination | Visual inspection, retention arm closure | Socket replacement, professional cleaning |

| Memory Modules | Slot damage, module substrate cracking | Clip engagement, POST verification | Module replacement, slot repair |

| Graphics Card | PCIe slot damage, mechanical stress | Secure mounting, display output test | Support installation, slot inspection |

| Power Connections | Incomplete insertion, connector damage | Firm seating, voltage verification | Connector replacement, cable rerouting |

| Motherboard Mounting | Standoff misalignment, PCB flexing | Even spacing, screw torque check | Remounting, standoff adjustment |

First Boot Procedures and System Verification

The initial system startup represents the culmination of the assembly process and the first opportunity to verify proper installation of all components. However, first boot procedures carry their own risks that can compound assembly errors or create new problems. Understanding proper startup sequences, diagnostic procedures, and recovery techniques becomes essential for completing a successful build without additional component damage.

Pre-boot verification involves systematic inspection of all connections, component seating, and physical installation before applying power. This inspection should include verification of all power connections, proper memory seating, graphics card installation, and cable routing. Additionally, checking for loose screws, foreign objects, or other potential problems prevents startup failures that could complicate diagnosis or cause additional damage.

Initial power application should follow a controlled sequence that allows for immediate shutdown if problems become apparent. Connecting only essential components for the first boot attempt simplifies troubleshooting and reduces the risk of cascading failures. The minimum configuration typically includes CPU, memory, graphics output capability, and storage, with additional components added after verifying basic functionality.

BIOS/UEFI initialization provides the first indication of successful component installation and system functionality. Modern systems perform extensive hardware detection and configuration during the boot process, providing detailed information about detected components and any configuration issues. Understanding normal boot sequences and common error indicators helps distinguish between minor configuration issues and serious hardware problems.

System stability testing extends beyond simple boot verification to include stress testing and thermal monitoring. Initial component installation may appear successful but fail under load conditions due to marginal connections or inadequate cooling. Comprehensive testing reveals these issues before they cause component damage or data loss during normal operation.

Advanced Damage Prevention Strategies

Professional PC building incorporates advanced techniques and equipment that go beyond basic assembly procedures to provide additional protection against component damage. These strategies become particularly important when working with expensive components or building systems for critical applications where failure cannot be tolerated. Understanding and implementing these advanced techniques significantly reduces the risk of both immediate damage and long-term reliability issues.

Component-level testing and verification involves using specialized equipment to verify proper component function before installation. Digital multimeters can verify power supply outputs and detect potential voltage irregularities before connecting sensitive components. Similarly, memory testing equipment can identify marginal memory modules that might cause system instability or component stress. While this equipment represents additional investment, it prevents far more expensive component failures.

Environmental monitoring throughout the assembly process provides early warning of conditions that could lead to component damage. Digital hygrometers monitor humidity levels that affect static electricity generation, while thermometers track temperature variations that could affect component handling or thermal paste application. Maintaining logs of environmental conditions helps identify patterns that correlate with assembly problems.

Documentation and photography of each assembly step creates a record that facilitates troubleshooting and prevents repeated mistakes. Photographing component serial numbers, BIOS settings, and physical configurations provides reference information for future maintenance or problem diagnosis. This documentation becomes particularly valuable for complex builds with numerous components or specialized configurations.

Quality control checklists ensure that all critical installation steps receive proper attention and verification. Professional assembly shops utilize detailed checklists that cover every aspect of the build process, from initial component inspection through final system testing. Adapting these professional practices to personal builds significantly improves assembly reliability and reduces the risk of component damage through oversight or rushed procedures.

Recovery and Repair Considerations

Despite careful preparation and proper technique, component damage occasionally occurs during PC assembly. Understanding available recovery options and when to seek professional assistance can mean the difference between minor setbacks and complete component loss. Additionally, proper diagnosis of assembly problems prevents unnecessary component replacement and identifies the actual source of issues.

Damage assessment requires systematic evaluation of symptoms and visual inspection to determine the scope and severity of problems. Some damage, such as bent socket pins or loose connections, may be repairable with proper tools and techniques. However, attempting repairs beyond one’s skill level can worsen the damage and eliminate professional repair options. Understanding these limitations helps make appropriate decisions about repair attempts versus professional service.

Professional repair services specialize in component-level diagnosis and repair that extends far beyond typical user capabilities. Modern motherboards and graphics cards utilize sophisticated multi-layer designs with embedded components that require specialized equipment and expertise to repair effectively. These services can often recover components that appear completely failed, making professional consultation worthwhile for expensive components.

Warranty considerations become important when component damage occurs during assembly. Many manufacturers void warranties for user-caused damage, making proper installation techniques crucial for maintaining warranty protection. However, some manufacturers offer builder support programs that provide assistance with installation problems or component compatibility issues. Understanding warranty terms and available support options helps navigate problems when they occur.

The evolution of PC building continues to introduce new technologies and form factors that require updated knowledge and techniques. Staying current with industry developments, manufacturer recommendations, and professional best practices ensures that building skills remain relevant and effective. The investment in proper knowledge, tools, and techniques pays dividends in successful builds and avoided component damage throughout years of PC assembly projects.

Building a personal computer successfully requires more than technical knowledge; it demands respect for the sophisticated engineering and precise manufacturing tolerances of modern components. Each component represents thousands of hours of development and precision manufacturing that can be undone in seconds through careless handling or improper installation. However, with proper preparation, appropriate techniques, and careful attention to detail, PC building remains an accessible and rewarding endeavor that provides both practical benefits and personal satisfaction. The key lies in understanding that successful building comes not from speed or shortcuts, but from methodical application of proven techniques that protect these remarkable technological achievements while creating powerful, reliable computer systems.

cpustorm.com

cpustorm.com